back40 bicycleworks frame building blog

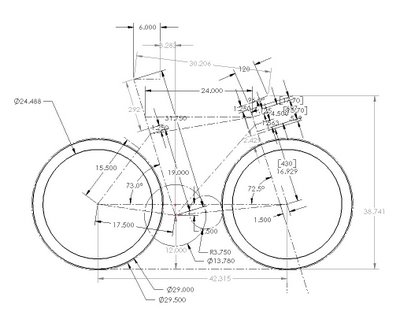

Over the next little while I will be posting here and documenting the build process I use to construct custom steel bicycle frames. I build as a hobby and have constructed about 20 frames to date. The build blog will chronicle the steps I take in building a 29" wheeled rigid mountain bike frame and fork. Stay tuned for photos and descriptions...